Process, Control & Instrumentation

Air Actuated Valve Training Rig

Designed to demonstrate the setting of an air actuated valve and other necessary components.

Through the use of an Auto/ Manual Loading Station the valve can either be actuated by a direct pneumatic feed or by a 4-20mA signal regulated and supplied by the Process Controller and IP Converter. The Rig can also be used for trainees to learn how to calibrate loop powered instrumentation whilst working with small bore instrumentation pipework.

Equipment included in the Rig include, Fisher air actuated valve and pneumatic valve positioner, Watson Smith remote manual and auto/manual loading station, ABB Process Controller, electronic current to pneumatic converter, digital pressure transmitter, analogue pressure gauge, 2-way manifold valves, 6mm small bore pipework & compression fittings.

Bench Mounted Pump & Motor Training Rig

Consists of a drip tray unit complete with carry handles on which the pump and motor mounting frame will be installed.

The unit comes compete with start / stop and emergency stop.

The pipework forms a closed loop to enable the unit to be charged with water to test the seals after the trainee has fitted the seals and aligned the pump and motor unit.

Fitted with a Liquid Ring Pump.

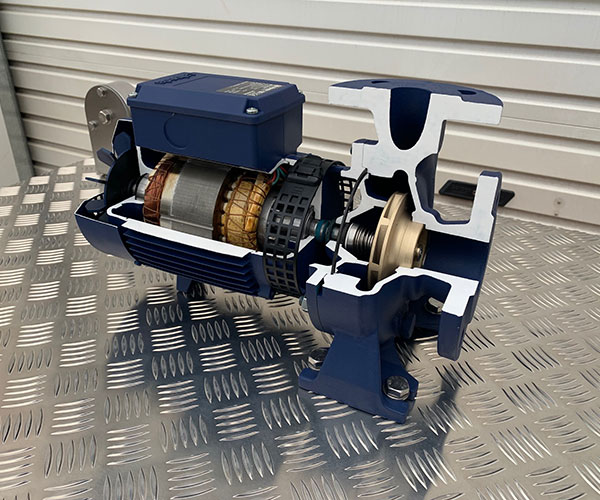

Centrifugal Pump Cutaway

Pump Cutaway with typical Mechanical Seal fitted (Bench Mounted).

Pump and seal may differ in size and manufacture to the one shown in the picture.

Electrical Valve Actuator Training Rig (Rotorq)

Designed to train technicians and apprentices in the programming and operation of an electric valve actuator in a safe, off line, environment.

Comprises: 110v Rotork IQS12 Valve Actuator fitted to an Orbinox 6” Knife Gate Valve. There is a small sectioned pipe spool mounted either side of the valve as well as a clear polycarbonate guard. All mounted on a polyester powder coated frame with swivel/lockable castors.

Other valves are available – please advise if you have a preference for a different manufacturer.

Flow Loop Multi-Purpose Training Rig

Designed to provide a wide variety of training opportunities, portable enough to allow it to be utilised in a training workshop.

The system is designed to run at low pressure, up to 3 bar, mounted on a Beta maxi tank mobile workbench with a 5-bar aluminium worktop mounted on a Box Section Frame fitted with swivel/lockable castors and lifting points, 2.6m wide, 1.75m deep and 2.4m high.

Equipment fitted includes a stainless-steel sump and drain point below open mesh flooring, 3-Phase supply control panel, Motor Start/Stop and E-Stop, 6 digital displays. Panel fitted with lockable isolator and flying lead. 24V Marshalling Panel for student access. Hot tank controller and indication. 2 off 0.75kW Close Coupled End Suction Centrifugal Pumps with packed glands (cold loop) – can be run individually, in parallel or in series through the use of 3-way valves ,cold loop pumps fitted double block and bleed setup, 1 off Circulating Pump (hot loop), 1 litre Plate Heat Exchanger coupled with hex unions. Pressure Gauges, 1 Pressure Transmitter, 1 Differential Pressure Transmitter and 2 Temperature Transmitters, Manifold valves to supply the pressure transmitters (2-way for PTx and 5-way for DPTx). Thermocouple indication from inlet and outlet of both tanks, Ammeters connected to cold pumps, Flow Indicator & Orifice Plate c/w Manometer fittings, Isolation valves and safety relief valve on each tank, 1 ¼” & 2” mild steel pipework on cold loop, 1 ¼” stainless steel pipework on hot loop , EPDM gaskets throughout, Mixture of couplings and valves, Low level fill point on each tank, Y-strainer basket filter, Sight glass on each tank, all powder coated or wet painted on completion.

Flow Loop Multi-Purpose Training Rig (Diaphragm Pump)

Designed to provide a wide variety of training opportunities, portable enough to allow it to be utilised in a training workshop.

The system is designed to run at low pressure, up to 3 bar, mounted on a Beta maxi tank mobile workbench with a 5-bar aluminium worktop mounted on a Box Section Frame fitted with swivel/lockable castors and lifting points, 2.6m wide, 1.75m deep and 2.4m high.

Equipment fitted includes a stainless steel sump and drain point below open mesh flooring, 3 Phase supply control panel, Motor Start/Stop and E-Stop, 6 digital displays. Panel fitted with lockable isolator and flying lead. 24V Marshalling Panel for student access. Hot tank controller and indication. 2 off 0.75kW Close Coupled End Suction Centrifugal Pumps with packed glands (cold loop) – can be run individually, in parallel or in series through the use of 3-way valves, Cold loop pumps fitted double block and bleed setup, 1 off Air Operated Diaphragm Pump (hot loop), 1 litre Plate Heat Exchanger coupled with hex unions. FRL & Pulsation Damper to support AOD Pump. 5 pressure gauges (at both the inlet and outlet of the cold pumps and on the common leg), 1 Pressure Transmitter, 1 Differential Pressure Transmitter and 2 Temperature Transmitters, Manifold valves to supply the pressure transmitters (2 -way for PTx and 5-way for DPTx). Thermocouple indication from inlet and outlet of both tanks , Ammeters connected to cold pumps, Flow Indicator & Orifice Plate c/w Manometer fittings, Isolation valves and safety relief valve on each tank , 1 ¼” & 2” mild steel pipework on cold loop , 1 ¼” stainless steel pipework on hot loop, EPDM gaskets throughout. A mixture of valves, Low level fill point on each tank, Y-strainer basket filter, Tanks non-pressurised, Sight glass on each tank, all powder coated or wet painted on completion.

Gland Packing Training Rig

Designed to assist in training staff in the correct method of fitting gland packing offline on a mobile Rig which can be used in a Training Workshop.

Mounted on a sub frame complete with Castors & comprises of a pump and motor unit complete with a Fabricated Stainless-Steel Tank, Pipe work, Valves, Gauge and Flanges.

Comes complete with an Electrical Control Panel with Emergency Stop fitted with flying lead Connection.

Instrumentation for Calibration Training Rig

Designed to provide initial training for technicians or apprentices, to calibrate instruments in a training environment before having to work on similar instruments within the the plant. Just in time training can also be carried out which would be relevant if an infrequently performed calibration is to be performed: the item on the Rig could be used as a practice calibration before working on the plant.

Mounted on a powder coated box section frame with a centrally mounted display board overlaid with polished aluminium sheet. The top surface & shelves are manufactured from aluminium 5 bar plate & the unit is carried on non-marking swivel brake castors.

Comprises both a straight pressure loop and a differential pressure loop, these are supplied by a rear mounted filter/regulator. Each instrument on the straight loop is fed by a 2-way calibration valve and the differential loop is fed by a 5- way manifold. There are a variety of switches, transmitters, gauges, displays and meters. The set-up enables training to ensure that the instruments are correctly isolated, vented, tested and de-isolated.

Instrumentation can be customised to meet customer site specific requirements.

Instrumentation for Calibration Training Rig (Roll Cab Mounted)

Mounted on a Beta Super Tank mobile workbench. The bench has been clad with a 5 bar aluminium worktop and the panel is cladded with brushed stainless steel.

Designed to allow trainees to demonstrate calibrate, maintain, set and service pressure switches and transmitters.

Supplied with a low pressure, small volume and portable air compressor enabling live testing in the training environment.

Can also be used for training on small bore pipework and fittings, both compression and screwed.

Level Flow Training Rig

This training rig consists of a mobile frame that supports various level and flow measurement and control components. Mounted on the lower shelf is a 100-litre stainless steel water storage tank, which supplies either of the rig’s two independent systems via a peripheral pump and an actuated T-port ball valve.

The water can be directed into one of two paths:

- A 45-litre clear acrylic water level measurement tank, or

- A series of clear acrylic flow measurement components, which are connected to a manometer board.

A check valve is installed between the storage tank and the pump to prevent backflow from the measurement tank when the pump is switched off. A bypass line with a manual ball valve is provided around the check valve, enabling drainage of trapped water from the flow system after operation, or to demonstrate siphoning from the measurement tank when required.

The water level measurement tank is equipped with:

- Three float switches for low, high, and high-high level alarms, used for automated pump control

- An ultrasonic level transducer mounted above the tank, with a connected air temperature sensor for automatic calibration

- A modulating actuated ball valve for tank drainage, returning water to the main storage tank

In addition, a bubble tube system is installed to enable level and density measurement via two differential pressure transmitters. Compressed air is supplied through the rig’s pressure regulator, which splits into three independent flow controllers:

- One controller vents to atmosphere

- Two supply dip leg tubes of varying lengths inside the tank

Manifold valves allow each transmitter to measure differential pressures:

- Transmitter 1: Pressure difference between the long dip leg and atmosphere

- Transmitter 2: Pressure difference between the long and short dip legs

Flow Measurement System Components

Sudden Enlargement

- Inlet Diameter: 17 mm

- Outlet Diameter: 27 mm

Venturi Tube

- Inlet/Outlet Diameter: 27 mm

- Throat Diameter: 13.5 mm

- Convergent Angle: 21°

- Divergent Angle: 8°

Orifice Plate

- Inlet/Outlet Diameter: 27 mm

- Orifice Diameter: 13.5 mm

- Effective Thickness: 0.54 mm

- Downstream Taper: 45°

- Rotameter

Flow Range: 150 – 1600 L/hr

Electrical and Control Systems

All electrical components are powered via a 415V AC control panel, which includes readout displays. Instrumentation signals are routed through a 24V DC marshalling cabinet, where knife-edge terminals allow individual devices to be safely isolated for calibration.

The rig is UKCA marked.

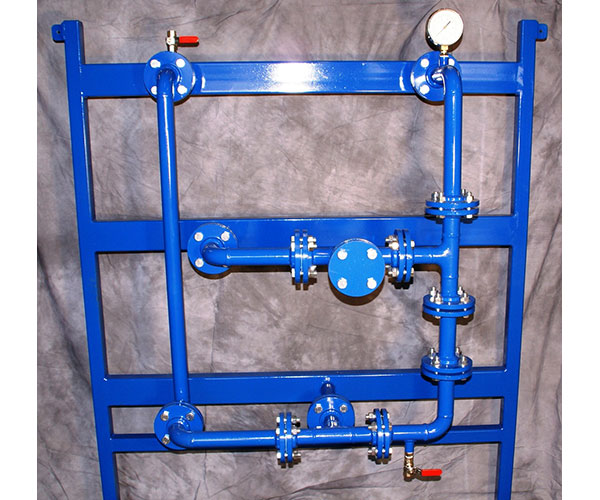

Mobile Pipework Training Rig

Designed to assist in the training of staff in the correct methods of assembling and lining up pipe work and flanges as well as gasket fitting and the controlled tightening of bolts.

Designed to be portable and easy to handle, manufactured in a robust construction mounted on heavy duty lockable swivel castors.

Pipe size/flanges/style can be tailored to individual site specific requirements. The rig is fitted with drain valves and pressure relief valves & is set with a working pressure of 3 bar.

Pressurised Pipe / Flange Fitting Training Rig

A wall mounted arrangement consisting of a 40NB Pipework manifold c/w flanges which will have a corresponding manifold and flanges to allow the trainees to simulate bolting together of pipework spools.

Incorporates a sealed ring main and includes the use of isolation ball valves to allow the unit to:

- Be pressurised

- Isolate a certain section

- Drain the section

- Remove the section

- Re-orientate

- Re-fit section

- Charge with water

- Pressurise to check the trainee has reconnected properly

Screwed Compression Fitting Training Rig

Comprised of a selection pipework diameters and materials, including Ø54mm and Ø20mm stainless steel, Ø35mm and Ø28mm zinc plated carbon steel, and Ø22mm and Ø15mm copper. The main Ø54mm stainless steel pipework loop is of welded construction. Ball valves are screwed into T-piece branches on this loop, to allow the other pipework systems to be connected.

These systems are assembled using a variety of different compression fittings, allowing them to be disassembled and rebuilt, for training purposes.

The main pipework loop also incorporates a fill valve, bleed valve, pressure gauge and 3 bar safety relief valve. This configuration allows the pipework to be filled with water under pressure, from a mains supply or independent pump, to facilitate leak detection procedures.

The entire assembly is fixed to a wall mountable powder coated carbon steel framework, using rubber lined anti-vibration pipe clips.

Sectional Valve Training Rig – Parallel Slide / Wedge / Globe / Ball / Non-Return

Valves are mounted on a powder coated box section frame which moves around easily on non-marking polyurethane castors.

Can be utilised as a display or teaching aid. The valves are fully functional and allow trainees to understand their inner workings.

We can supply a set of sectional valves to suit specific site requirements.